x

x x

xThe paper manufacturing process involves, sheet forming, wet pressing, drying, coating, surface sizing drying, calendaring and winding. In some modern paper machines all of these unit operations are accomplished on a single line. Precision variable-speed and torque-controlled drives, which are usually combined to form a network of sectional drives, provide the machines with the power they need; a large number of single drives are also required around the machine for pumps and fans. Sectional drives are required for paper and coating machines, winders, and other machines through which materials pass. The drive systems must be coordinated in such a way that they can control machine operating speeds without any web break.

PROCESS DESCRIPTION

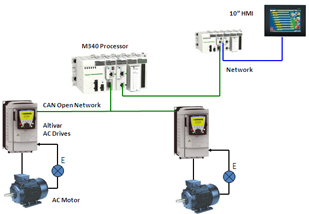

SYSTEM CONFIGURATION

A paper machine has several separate sections which are run by electrical motor and drive combination. These motors drive separate sections to which a Wire section, Press sections, Dryer sections and then Calendar & Pope Reel are connected. The surface speeds of all these sections are synchronized through control system. These sections will have independent AC motors which will have independent digital AC drives. The main function of the control system is to synchronize the speeds of these sections with respect to each other.